Description

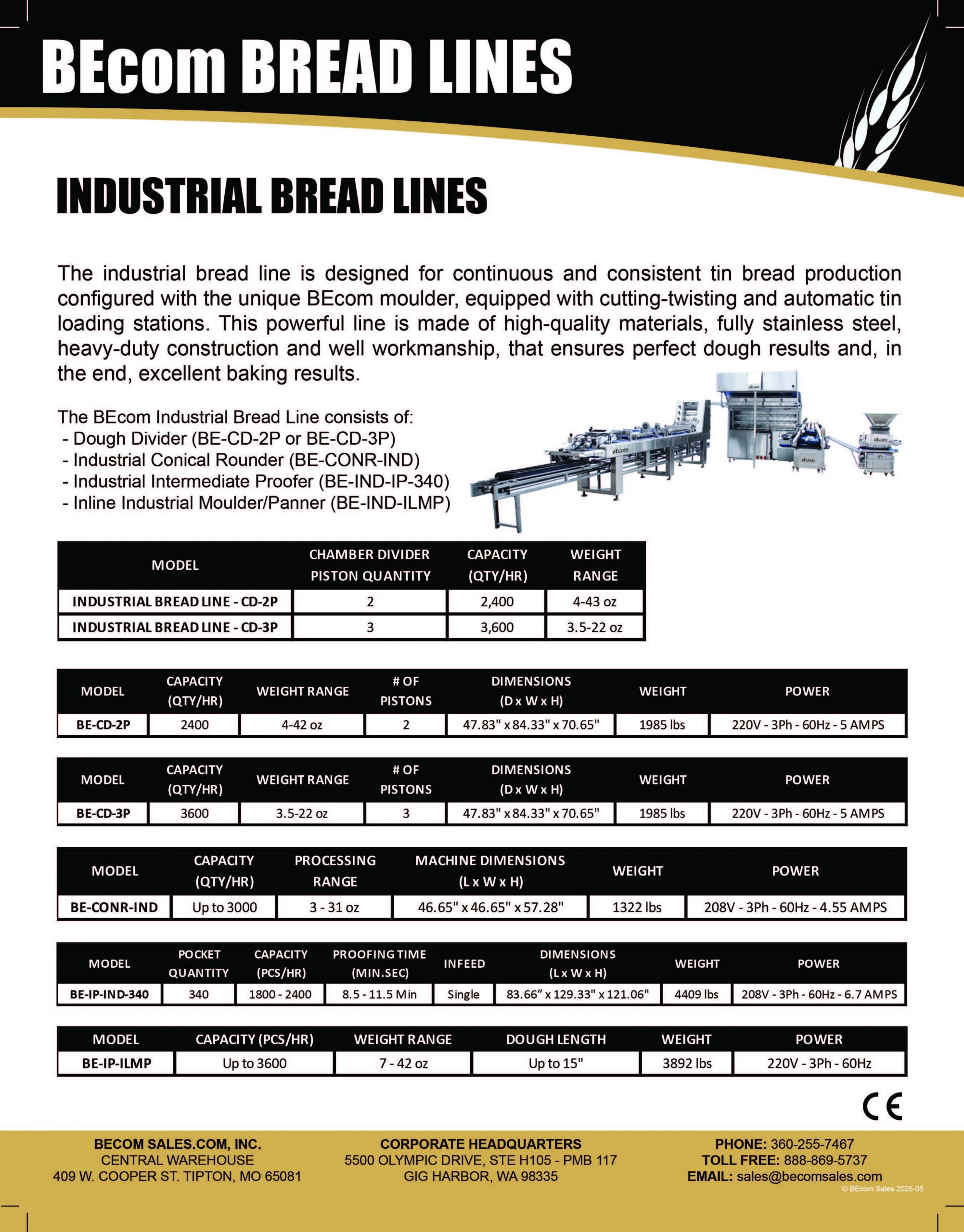

The industrial bread line is designed for continuous and consistent tin bread production configured with the unique BEcom moulder, equipped with cutting-twisting and automatic tin loading stations.This powerful line is made of high-quality materials, fully stainless steel, heavy-duty construction and well workmanship, that ensures perfect dough results and, in the end, excellent baking results.

The line has two different capacities depending on the divider preferred, Model: BE-CD-2P or Model: BE-CD-3P:

Up to 2,400pcs/hr dough weight range between 4oz-43oz

Up to 3,600pcs/hr dough weight range between 3.5oz-22oz

Dough Divider, Model: BE-CD-2P

– Dividing chamber, main piston, measuring piston, hopper base made of Ni-Resist material (wear-corrosion and oxidant resistant).

– Crankshaft made from cast iron.

– BEKA brand oiling pump with 6 fixed dosing valves.

– Drop hopper has a volume of 55 gallons and made from stainless steel.

– Outer covers made of stainless steel.

– Analog weight adjustment with position indicator.

– Analog pressure adjustment of spring with position indicator.

– Variable speed inverter.

– 1.8 gallon oil reservoir, stainless steel indicator of insufficient oil supply.

– Cross discharge conveyor, (left or right hand side must be specified when placing order.)

Industrial Conical Rounder, Model: BE-CONR-IND

– Fully stainless-steel frame and surrounding panels

– Cast iron Teflon coated cone

– Aluminum tracks, in and outside Teflon coated

– Cast aluminum crumb collection tray, Teflon coated

– Cone speed controller by inverter

– Cone with top bearing

– Stainless steel round head cover

– Automatic flour duster

– Stainless steel swivel castors with mounting pins

– Easy in operation and cleaning

– Perfect separation between dough pieces coming from the divider

– Perfect transfer of dough pieces with outfeed chute

Industrial Intermediate Proofer, Model: BE-IND-IP-340

– Fully stainless-steel frame, swings and surrounding panels modular system – unmounted

– Nylon-mesh round pockets, easy to remove for cleaning

– 10 pocket modulated standard in all models on swings

– infeed conveyor, with photocell control with continuous drive. Flour duster on infeed conveyor

– Collection drawers for adjustable resting time, to able to exit of dough pieces as refer desired proofing time

– Outfeed cross conveyor

Synchronized speed controller with the divider

– Electrical cabinet at working height with power supply and sockets for divider, rounder and moulder

– Air circulation fan

– UV lightening

– Flexible layout with the choice of infeed position; side right or left and front or rear must be specified with the order.

– Electrotechnical control panel

Inline Industrial Moulder/Panner, Model: BE-IND-ILMP

– Fully stainless-steel frame and surrounding panels

– Fully automatic twisting and panning

– Bypass of twisting station for open loaves

– Blue color cleanline belt, coated with polyolefin material

– Knife station for complete and partial cutting

– Discharge stainless steel belt to transfer loaves

– Infeed conveyor

– Adjustable centering rollers on infeed conveyor

– Driven pressure roller adjustable by position indicator

– 3 pairs of adjustable sheeter and gear drive on rollers

– Adjustable speed by frequency inverter

– Adjustable wire belt for pre-molding with separated conveyor

– Individually adjustable conveyor speed by frequency inverter

– Height adjustable fixed and motorized-conveyed combined pressure boards

– Air blowing fans on sheeting rollers, pre-molding belt and pressure board

– Parallel adjustable side guides to fix length of loaves